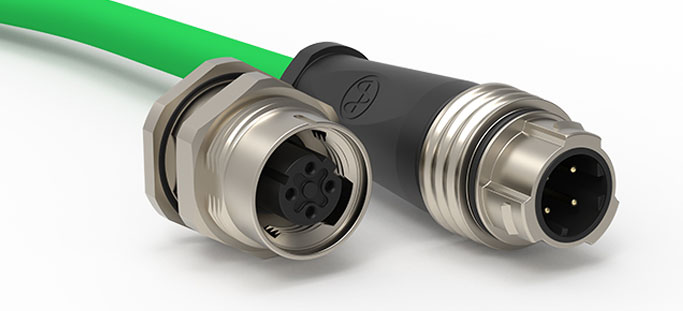

M12 connectors are a cornerstone of industrial automation and control systems due to their compact design, reliability, and versatility. They are used for connecting sensors, actuators, field devices, and even industrial Ethernet networks. One important consideration when selecting M12 connectors is whether to use shielded or unshielded versions. The choice significantly impacts electrical performance, noise immunity, and suitability for specific applications. Understanding the differences helps engineers and technicians optimize system reliability and performance.

The M12 connector features a 12-millimeter threaded coupling, multiple pin configurations, and various coding options that support power, signal, and data transmission. Shielding plays a crucial role in maintaining signal integrity, especially in environments with electromagnetic interference (EMI) or radio-frequency interference (RFI). The M12 Connector is available in both shielded and unshielded versions, and detailed specifications of the M12 Connector highlight the scenarios where each type is appropriate for industrial applications.

Understanding Shielding in M12 Connectors

Shielding in M12 connectors involves adding a conductive layer around the internal wires or contacts to prevent external electrical noise from interfering with the signals. This shielding can be achieved through metal housings, braided wire shields, or foil wraps. The shield is typically grounded to allow the interference to be safely diverted away from the signal-carrying conductors. Shielded connectors are particularly important in high-speed data applications, sensitive sensor signals, or electrically noisy environments.

Unshielded M12 connectors, on the other hand, do not include this protective layer. They rely solely on the natural electrical isolation provided by insulation materials and the connector design. While sufficient for low-speed or short-distance signal transmission, unshielded connectors may be vulnerable to EMI and RFI in industrial settings with motors, drives, welding equipment, or high-power switching devices.

Electrical Performance and Noise Immunity

The primary difference between shielded and unshielded M12 connectors lies in their ability to handle electromagnetic interference. Shielded connectors are designed to maintain signal integrity by preventing noise from distorting the transmitted data or power. This is crucial in applications such as industrial Ethernet (PROFINET, EtherNet/IP), high-frequency sensors, or long cable runs where signal quality must remain high.

Unshielded M12 connectors are suitable for applications where electromagnetic interference is minimal. Examples include short cable runs, low-speed sensor connections, or simple actuator controls. While they are cost-effective and simpler to install, they do not provide the additional protection needed in electrically noisy environments.

Mechanical Design Considerations

Shielded M12 connectors often feature metal housings that contribute to both shielding and mechanical strength. The metal housing can also improve durability and provide better resistance to mechanical stress, vibration, and environmental conditions. Grounding of the shield is typically achieved through the connector body, ensuring consistent performance against interference.

Unshielded connectors usually have plastic housings that are lightweight and more flexible in compact installations. While they offer adequate protection against dust and moisture in IP-rated connectors, they lack the EMI protection provided by metal housings or additional shielding layers. Installation environments and mechanical stress requirements can influence whether a shielded or unshielded connector is preferred.

Application Scenarios

Shielded M12 connectors are ideal for industrial Ethernet networks, high-speed sensors, and environments with significant electrical noise. They are commonly used in factory automation, robotic systems, motion control, and machinery near high-power equipment. Shielding ensures stable data transmission, minimizes errors, and prevents communication disruptions.

Unshielded M12 connectors are sufficient for low-speed signals, simple sensor connections, and short-distance wiring in low-interference environments. They are commonly found in packaging machinery, conveyor systems, and small automated equipment where electrical noise is minimal. Unshielded connectors are generally less expensive and easier to handle in high-density installations.

Installation and Grounding Considerations

When installing shielded M12 connectors, grounding is critical to achieve proper noise protection. The shield must be connected to the grounding system or the device’s chassis, ensuring that any interference is safely diverted. Improper grounding can reduce the effectiveness of the shield and compromise signal integrity.

Unshielded connectors do not require grounding, simplifying installation. However, in applications where EMI may be present, choosing an unshielded connector without considering the environment can lead to signal degradation, data errors, or operational issues.

Cost and Selection Considerations

Shielded M12 connectors are generally more expensive than unshielded versions due to their added materials and construction complexity. They also require careful installation to ensure proper grounding and performance. However, the investment is justified in applications where data integrity, EMI resistance, and reliability are critical.

Unshielded connectors are cost-effective and suitable for low-risk environments, but they may require additional protection measures if EMI becomes a factor. Selection should be based on cable length, signal type, environmental noise, and the importance of uninterrupted operation.

Conclusion

The choice between shielded and unshielded M12 connectors depends on the application requirements, electrical environment, and performance expectations. Shielded connectors provide enhanced noise immunity, better mechanical durability, and reliable data transmission in electrically noisy or high-speed applications. Unshielded connectors are suitable for low-speed signals, simple sensor connections, and environments with minimal interference. By evaluating electrical performance, environmental conditions, and installation requirements, engineers and technicians can select the appropriate M12 connector type to ensure reliable, efficient, and durable operation in industrial systems.