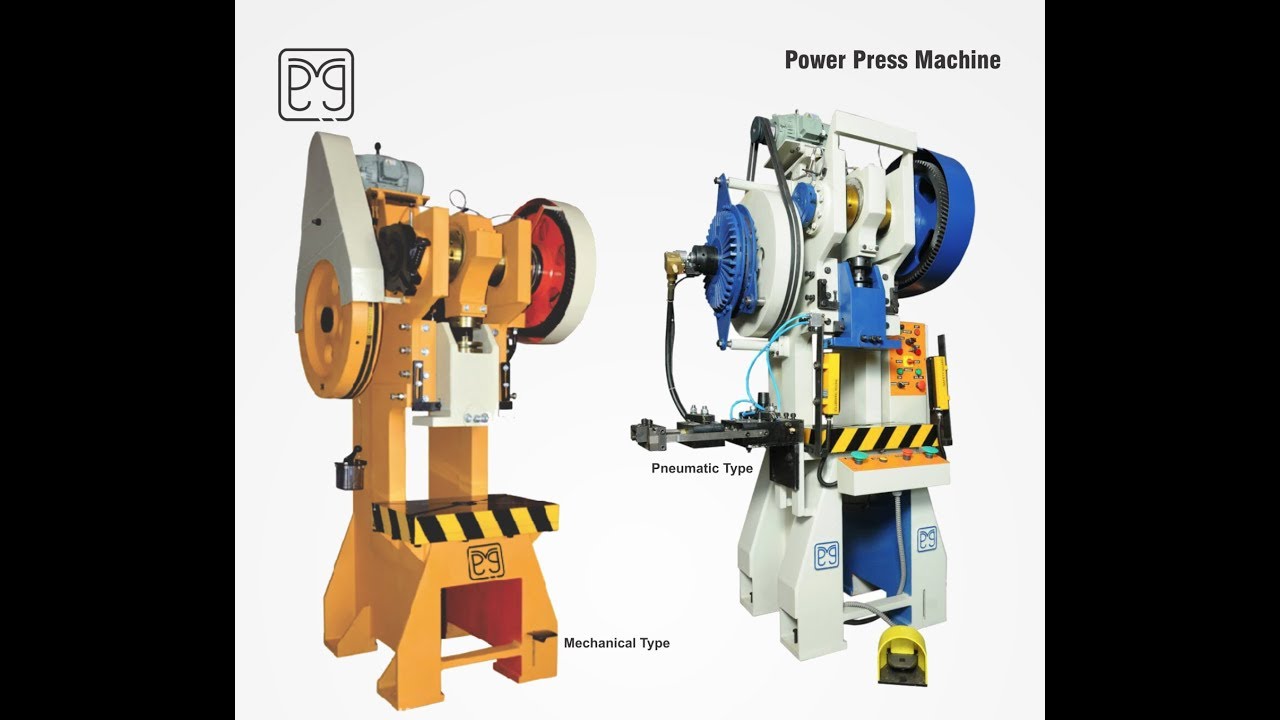

Power press machines are essential equipment in metalworking and manufacturing industries, widely used for operations such as punching, bending, shearing, and forming metal sheets. The quality, efficiency, and safety of these machines depend heavily on the manufacturing standards followed by their producers. Adhering to strict standards ensures that the machines operate reliably, produce consistent results, and meet industry safety requirements.

A Power Press Machine Manufacturer is responsible for designing and producing presses that meet rigorous standards in terms of structural integrity, precision, and safety. By following established manufacturing norms, these producers ensure that their machines can withstand high operational forces, minimize mechanical failures, and provide long-term durability. Compliance with international standards also enables manufacturers to deliver machines suitable for global markets.

Importance of Manufacturing Standards

Manufacturing standards are critical for several reasons. First, they ensure the safety of operators by incorporating design elements that minimize risks during operation. Second, they guarantee that the press maintains consistent performance and accuracy, which is vital for industrial applications where precision is required. Third, adherence to standards contributes to the longevity and durability of the machines, reducing maintenance costs and downtime. Without strict standards, machines may suffer from structural weaknesses, misalignment, or unsafe operation, posing a risk to personnel and production quality.

Key Standards Followed by Producers

Several key manufacturing standards guide the production of power press machines. These standards cover aspects such as design, materials, safety, testing, and performance.

1. ISO Standards

The International Organization for Standardization (ISO) sets global benchmarks for quality management, safety, and operational efficiency. Many power press producers follow ISO 9001 standards for quality management systems, ensuring that production processes are well-documented, controlled, and continuously improved. ISO standards also cover environmental management, which ensures sustainable and responsible manufacturing practices.

2. CE Marking and European Safety Standards

For manufacturers targeting the European market, CE marking is mandatory. This certification indicates compliance with European directives, particularly those related to machinery safety. Power press machines must meet requirements such as proper guarding, emergency stops, electrical safety, and noise control. CE-compliant presses demonstrate that the manufacturer prioritizes operator safety and regulatory adherence.

3. Material and Structural Standards

Producers use high-grade materials for critical components such as the frame, ram, flywheel, and bed. Standards for material strength, hardness, and fatigue resistance ensure that the press can withstand repeated high-force operations without deforming. Structural design standards also dictate tolerances and alignment criteria to maintain accuracy and minimize vibration during operation.

4. Safety and Protective Standards

Safety standards govern the design of guards, two-hand control systems, light curtains, and other protective devices. Adherence to these standards ensures that the press operates safely, preventing accidental access to moving parts and reducing the risk of injuries. Manufacturers also follow standards for operator training manuals and emergency protocols to enhance workplace safety.

5. Testing and Performance Standards

Before a press reaches the customer, manufacturers conduct extensive testing to verify its performance. Standards dictate tests for load capacity, stroke accuracy, ram alignment, and operational stability. Hydraulic and mechanical presses are tested under maximum rated tonnage to ensure that the machine can operate safely under full load. Consistent testing guarantees that each unit meets the required performance criteria.

Benefits of Following Manufacturing Standards

Adhering to manufacturing standards provides several advantages to both producers and end-users. These include:

- Enhanced Safety: Proper design and testing reduce the risk of accidents.

- Consistency: Machines perform reliably and maintain precision over time.

- Durability: Quality materials and structural standards extend the machine’s service life.

- Global Market Access: Compliance with international standards allows manufacturers to sell their machines worldwide.

- Customer Trust: Buyers are more confident in machines that meet recognized standards, which increases brand reputation.

Conclusion

Manufacturing standards followed by power press machine producers play a vital role in ensuring the safety, efficiency, and longevity of these machines. From material selection and structural integrity to safety devices and performance testing, adherence to standards ensures that presses operate reliably and meet industrial requirements. Producers that comply with ISO certifications, CE marking, and other recognized standards demonstrate their commitment to quality and customer satisfaction. By understanding these standards, manufacturers, operators, and buyers can make informed decisions, ensuring that their production facilities are equipped with reliable and safe machinery.