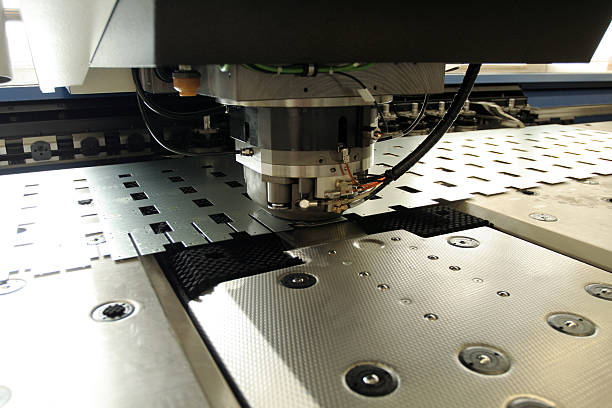

A power punch machine is a vital tool in modern metal fabrication, offering precision, speed, and versatility in cutting, shaping, and forming metal sheets. Understanding the key components of a power punch machine is essential for operators, maintenance personnel, and purchasing managers. Familiarity with these components not only helps in choosing the right machine but also ensures safe and efficient operation, proper maintenance, and longer equipment lifespan.

The Frame and Base

The frame forms the backbone of a power punch machine, providing structural support and stability. Typically constructed from high-strength steel or alloys, the frame is designed to withstand high punching forces without flexing or deforming. The base supports the entire machine and often includes mounting points to secure the equipment to the workshop floor. A sturdy frame ensures that the machine remains rigid during operation, maintaining precision and preventing vibrations that could affect performance. The quality of the frame is a key factor in the overall durability and reliability of the power punch machine.

Punch and Die Assembly

The punch and die assembly is the heart of a power punch machine. The punch is the tool that applies force to the metal sheet, cutting or shaping it against the die. The die provides a matching surface that ensures accurate and clean cuts. Power punch machines are designed to accommodate different punch and die sets, allowing for versatility in producing various shapes, holes, and patterns. The punch and die must be precisely aligned, and they are often made from hardened steel to resist wear and ensure long-term performance. Leading Power Punch Machine manufacturers provide high-quality punch and die assemblies to maximize precision and reduce maintenance requirements.

Ram or Slide

The ram, also called the slide, is the moving part of the machine that drives the punch toward the die. The ram is guided by the frame and typically moves vertically, applying controlled force to the punch. In mechanical power punch machines, the ram is powered by a crankshaft or flywheel system, while in hydraulic machines, it is driven by hydraulic cylinders. Accurate movement of the ram is crucial for consistent punching results, and precision guides and bearings are used to ensure smooth operation.

Drive System

The drive system provides the power needed to operate the machine. Mechanical power punch machines often use electric motors, flywheels, and crank mechanisms to generate punching force. Hydraulic machines rely on pumps and fluid pressure to move the ram, providing smoother and more adjustable force. Modern machines may also incorporate servo motors and electronic drives, allowing precise control over speed, stroke, and force. The efficiency and reliability of the drive system directly affect the machine’s performance and productivity.

Control System

The control system of a power punch machine is responsible for regulating its operation. Manual machines may have simple switches and levers, while advanced models feature programmable logic controllers (PLCs) or computer numerical control (CNC) interfaces. These systems allow operators to program punching sequences, adjust parameters such as stroke length and force, and monitor the machine’s performance in real time. An advanced control system improves accuracy, reduces errors, and enhances productivity, especially in high-volume or complex fabrication tasks.

Material Handling and Feeding Mechanisms

Efficient material handling is crucial for continuous operation. Many power punch machines are equipped with automated feeders, conveyors, or robotic arms to position metal sheets accurately under the punch. These systems reduce manual labor, improve safety, and ensure consistent punching results. For high-volume operations, integrated material handling allows the machine to operate continuously without operator intervention, significantly enhancing productivity.

Safety Features

Safety is a critical aspect of any power punch machine. Modern machines are equipped with emergency stop buttons, light curtains, protective guards, and two-hand control systems to minimize the risk of accidents. Some models also include sensors to detect material misalignment or overload conditions. By integrating robust safety features, manufacturers ensure that operators are protected while maintaining efficient production.

Conclusion

Understanding the key components of a power punch machine is essential for anyone involved in metal fabrication. The frame and base provide stability, while the punch and die assembly delivers precision cutting and shaping. The ram and drive system ensure controlled force, and advanced control systems enhance accuracy and automation. Material handling mechanisms improve efficiency, and safety features protect operators from potential hazards. Familiarity with these components helps businesses select the right machine, perform proper maintenance, and operate it safely and effectively. Investing in a high-quality Power Punch Machine ensures reliable performance, consistent results, and long-term value for industrial operations.