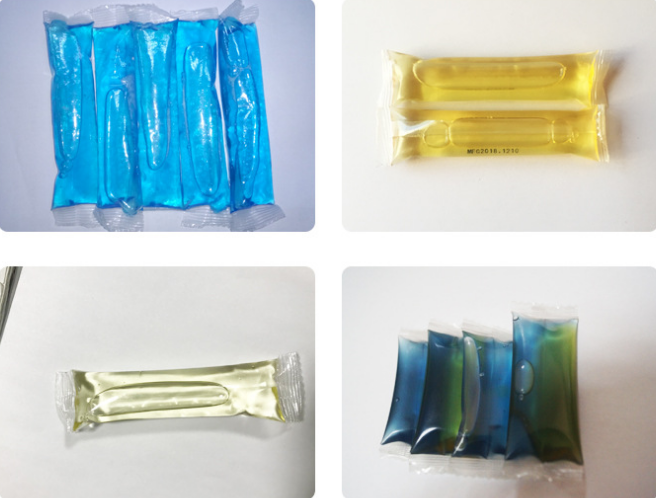

Sustainable packaging has become a central focus for manufacturers as industries respond to environmental concerns, regulatory pressure, and changing consumer expectations. Traditional plastic packaging, while effective, contributes significantly to pollution and long-term waste. In contrast, water soluble packaging offers an innovative solution by using materials that dissolve completely in water, leaving no harmful residue. Water soluble packaging machines make this solution scalable, efficient, and commercially viable for a wide range of industries.

These machines are designed to produce packaging that combines functionality with environmental responsibility. By automating the process of forming, filling, and sealing water soluble films, manufacturers can maintain high production standards while reducing their environmental footprint. As sustainability shifts from a trend to a necessity, understanding the benefits of water soluble packaging machines is essential for businesses aiming to stay competitive and responsible.

Environmental Advantages of Water Soluble Packaging

One of the most significant benefits of using water soluble packaging machines is their positive impact on the environment. Water soluble films, often made from polyvinyl alcohol, dissolve harmlessly in water and biodegrade naturally. This eliminates plastic waste that would otherwise end up in landfills, oceans, or incineration systems.

By adopting water soluble packaging, companies can significantly reduce their reliance on single-use plastics. This supports global efforts to reduce pollution and aligns with sustainability goals set by governments and environmental organizations. For brands, this shift also demonstrates a clear commitment to eco-friendly practices, which can strengthen consumer trust and brand reputation.

Improved Safety and Handling Efficiency

Water soluble packaging greatly enhances safety, particularly when dealing with hazardous, toxic, or highly concentrated products. Because the packaging dissolves without needing to be opened, users avoid direct contact with the contents. This is especially important in industries such as agriculture, chemicals, and cleaning products, where exposure risks are high.

In the middle of this process, the Water Soluble Packaging Machine plays a critical role by ensuring precise dosing and secure sealing of each package. This level of accuracy not only protects end users but also improves workplace safety during manufacturing, reducing spills, exposure, and contamination risks. As a result, companies benefit from safer operations and fewer liability concerns.

Cost Efficiency and Waste Reduction

Although water soluble packaging machines require an initial investment, they offer long-term cost advantages. Precise filling systems reduce product overuse and spillage, ensuring that each package contains the exact required amount. This accuracy helps minimize material waste and improves overall production efficiency.

Automation also reduces labor costs by streamlining packaging operations. Fewer manual handling steps mean faster production cycles and lower chances of human error. Over time, these efficiencies translate into significant cost savings, making water soluble packaging machines a financially sound choice for manufacturers focused on sustainable growth.

Versatility Across Multiple Industries

Water soluble packaging machines are highly versatile and can be adapted for various applications. In the detergent industry, they are widely used to produce laundry and dishwasher pods. In agriculture, they package fertilizers, herbicides, and pesticides in pre-measured doses that dissolve directly in spray tanks.

The pharmaceutical and chemical sectors also benefit from this technology by ensuring safe handling of potent substances. Even food and beverage processing industries are beginning to adopt water soluble packaging for additives, flavorings, and cleaning agents. This adaptability allows manufacturers to serve multiple markets with a single packaging solution.

Compliance with Sustainability Regulations

As governments around the world introduce stricter environmental regulations, businesses are under increasing pressure to adopt sustainable packaging solutions. Water soluble packaging machines help manufacturers comply with these regulations by reducing plastic usage and improving waste management practices.

Using eco-friendly packaging can also simplify compliance with international standards and certifications related to sustainability. This regulatory alignment not only reduces legal risks but also opens doors to new markets where environmentally responsible packaging is a requirement rather than an option.

Enhanced Brand Image and Consumer Appeal

Consumers are becoming more environmentally conscious and are actively choosing brands that demonstrate sustainable practices. Water soluble packaging offers a clear and visible commitment to environmental responsibility, which can positively influence purchasing decisions.

By investing in water soluble packaging machines, companies can differentiate themselves in competitive markets. Sustainable packaging can be highlighted as a key product feature, enhancing brand value and customer loyalty. Over time, this positive perception can translate into stronger market positioning and increased sales.

Long-Term Sustainability and Future Growth

Water soluble packaging machines support long-term sustainability by combining environmental benefits with operational efficiency. As technology advances, these machines continue to improve in speed, precision, and energy efficiency, making them even more attractive for large-scale production.

Looking ahead, the demand for sustainable packaging solutions is expected to grow steadily. Companies that adopt water soluble packaging machines early are better positioned to adapt to future regulations, consumer preferences, and market trends. In this way, water soluble packaging is not just a responsible choice, but a strategic investment in the future of manufacturing.