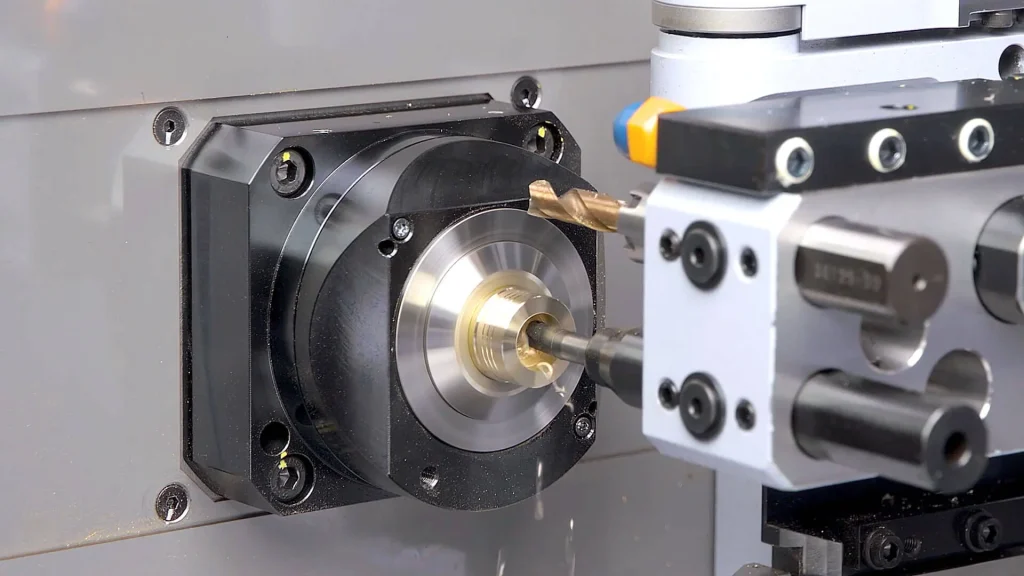

Automation has become a cornerstone of modern manufacturing, enabling companies to increase productivity, improve precision, and reduce operational costs. Swiss lathe machines, known for their ability to produce small, complex components with high accuracy, benefit significantly from automation. Integrating automated systems into Swiss lathe operations offers numerous advantages across efficiency, quality, and workflow management.

Enhanced Productivity

One of the primary benefits of automation is the significant boost in productivity. Automated Swiss lathe machines can operate continuously with minimal human intervention, reducing downtime between operations. Features such as bar feeders, automatic tool changers, and programmed machining cycles allow the machine to perform multiple tasks consecutively without requiring operator adjustments. This uninterrupted workflow increases output, making it possible to meet tight production deadlines and handle larger batch sizes efficiently.

Improved Accuracy and Consistency

Automation reduces the potential for human error, a common source of inconsistencies in manual machining. CNC-controlled Swiss lathe machines maintain precise tool paths, spindle speeds, and feed rates, ensuring each part meets exact specifications. This level of precision is especially important for industries such as medical devices, aerospace, and electronics, where tight tolerances and consistent quality are crucial. Implementing an swiss lathe machine with automation ensures repeatable results across multiple production runs, enhancing product reliability and reducing scrap.

Reduced Labor Costs

Automating processes on a Swiss lathe machine reduces the need for constant operator supervision. Operators can focus on higher-value tasks, such as programming, quality control, and machine maintenance, rather than performing repetitive manual operations. This reduction in labor requirements lowers operational costs while improving efficiency. Additionally, automation allows facilities to maintain consistent production levels even during periods of labor shortages.

Shorter Cycle Times

Automated operations minimize the delays associated with manual intervention, such as tool changes, material handling, or adjustments between operations. Swiss lathe machines equipped with live tooling and automated systems can perform multiple machining processes in a single setup, eliminating the need for secondary operations. This reduction in cycle time not only increases throughput but also accelerates the delivery of finished parts to clients, providing a competitive advantage in fast-paced manufacturing environments.

Enhanced Safety

Automation also contributes to safer working conditions. By reducing the need for operators to be in close proximity to rotating spindles, cutting tools, or material handling areas, the risk of accidents decreases. Automated systems handle potentially hazardous tasks such as bar feeding, part loading, and chip removal, while operators can monitor operations from a safe distance. Safety features integrated into modern Swiss lathes, combined with automation, further mitigate workplace hazards.

Better Resource Management

Automated Swiss lathe machines allow for optimized use of materials and tooling. Consistent tool paths and precise machining reduce material waste and extend the life of cutting tools. In addition, automated monitoring systems can alert operators when tools need maintenance or replacement, preventing unnecessary downtime and ensuring efficient use of resources. This approach minimizes production costs while maintaining high-quality output.

Flexibility and Adaptability

Automation does not only benefit high-volume production. Modern Swiss lathe machines can be programmed for small-batch or customized production without significant setup changes. Automated systems can quickly switch between part designs, tooling configurations, or materials, allowing manufacturers to adapt to changing production demands. This flexibility is invaluable for companies that produce a variety of components or operate in industries with frequent design modifications.

Data Collection and Process Optimization

Automated Swiss lathes often include integrated monitoring and data collection features. These systems track performance metrics, tool wear, cycle times, and production quality, providing valuable insights for continuous process improvement. Manufacturers can analyze this data to identify bottlenecks, optimize tool paths, and reduce defects, creating a more efficient and cost-effective workflow over time.

Conclusion

Automating processes with a Swiss lathe machine offers numerous advantages, including increased productivity, improved accuracy, reduced labor costs, shorter cycle times, enhanced safety, better resource management, and operational flexibility. By integrating automation into precision machining, manufacturers can achieve consistent quality, lower operational risks, and optimize overall workflow efficiency. Embracing automation ensures that Swiss lathe operations remain competitive, reliable, and capable of meeting the demands of modern manufacturing environments.