In today’s competitive manufacturing environment, innovation is key to maintaining efficiency, precision, and productivity. Swiss lathes have long been recognized for their ability to produce intricate components with tight tolerances, but continuous advancements from manufacturers are further transforming production processes. Understanding how these innovations impact workflow can help businesses make smarter equipment investments.

Enhanced Automation and Efficiency

One of the most notable ways Swiss lathe manufacturers drive innovation is through automation. Modern machines often include automatic tool changers, bar feeders, and robotic part loaders, reducing manual intervention and allowing continuous production. This not only increases efficiency but also minimizes human error, ensuring that each part meets exact specifications. Automation innovations enable workshops to handle higher production volumes without compromising precision.

Integration of Advanced Technology

Technological advancements in control systems, software, and sensors have greatly enhanced Swiss lathe performance. Machines now feature advanced CNC systems, real-time monitoring, and predictive maintenance tools, allowing operators to optimize processes and detect potential issues before they cause downtime. A reputable swiss lathe manufacturers integrates these cutting-edge technologies into their machines, providing equipment capable of delivering superior accuracy and repeatability across complex production tasks.

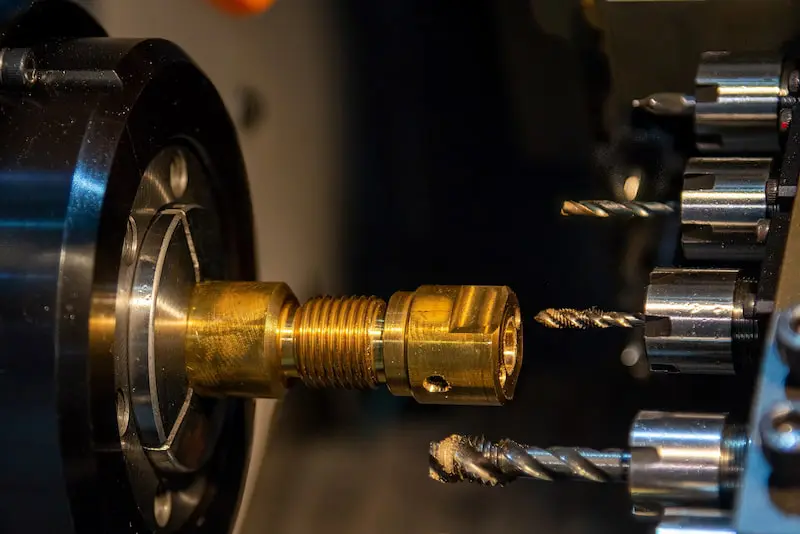

Multi-Axis and Multi-Function Capabilities

Innovation has also expanded the functionality of Swiss lathes. Multi-axis designs and multi-function capabilities allow for turning, drilling, and threading in a single setup. By performing multiple operations without transferring parts between machines, workshops can reduce cycle times and maintain tighter tolerances. Manufacturers who invest in these advancements help customers achieve faster production, higher precision, and lower operational costs.

Material Versatility and Durability

Modern Swiss lathe innovations extend to material handling and durability. Newer models are designed to process a wider range of materials, including metals, plastics, and composites, without compromising performance. Innovations in spindle design, tool holders, and wear-resistant components increase machine longevity and reliability. These improvements allow manufacturers to broaden their product offerings while maintaining quality standards.

Data-Driven Production Optimization

Swiss lathe manufacturers are increasingly integrating data-driven capabilities into their machines. Embedded sensors provide insights into spindle load, tool wear, vibration, and temperature. This real-time data enables operators to make informed decisions, optimize cutting parameters, and schedule maintenance proactively. Such innovations not only enhance production efficiency but also extend the life of the machine and tooling.

Energy Efficiency and Sustainability

Sustainability is becoming a key focus in machine design. Innovative Swiss lathes are built with energy-efficient motors, optimized cooling systems, and low-maintenance components. These features reduce energy consumption and minimize environmental impact while maintaining high productivity. Manufacturers prioritizing eco-friendly innovations allow workshops to meet sustainability goals without compromising operational performance.

Training and User-Friendly Interfaces

Another area of innovation involves operator experience. Modern Swiss lathes are equipped with intuitive interfaces, touchscreen controls, and programmable cycles that simplify operation. Manufacturers often provide comprehensive training and support, ensuring that operators can fully leverage the machine’s capabilities. These enhancements reduce setup times, minimize errors, and improve overall workflow efficiency.

Conclusion

Innovations from Swiss lathe manufacturers have a profound impact on production, enhancing automation, technological capabilities, multi-functionality, material versatility, data-driven optimization, energy efficiency, and operator experience. By embracing these advancements, workshops can achieve higher precision, increased productivity, and lower operational costs. Investing in innovative Swiss lathes ensures that manufacturers remain competitive and capable of meeting evolving industry demands while maintaining exceptional quality.