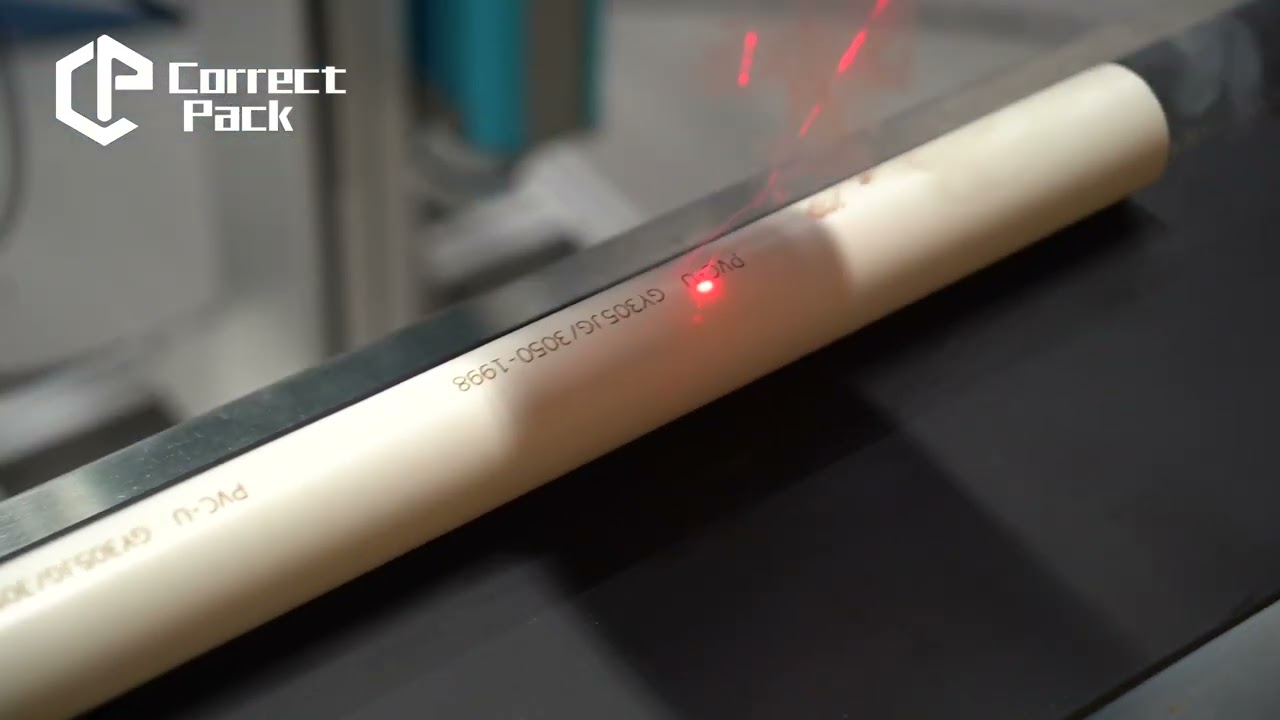

In modern manufacturing, product traceability has become a critical factor for quality control, regulatory compliance, and consumer safety. Traceability allows manufacturers to track products through every stage of production, packaging, and distribution. A Small Character Inkjet Printer is an essential tool in achieving this level of precision, providing reliable and efficient coding that ensures every product can be accurately identified and traced.

Investing in a reliable Small Character Inkjet Printer allows manufacturers to automate coding processes, reduce human error, and maintain consistent product identification. By printing batch numbers, expiration dates, serial numbers, and barcodes directly onto products or packaging, these printers enable comprehensive traceability throughout the supply chain.

The Importance of Traceability in Manufacturing

Traceability is crucial for multiple reasons. It helps manufacturers identify defective products quickly, facilitates effective recalls, ensures compliance with industry regulations, and builds consumer trust. Without reliable traceability, errors in production or labeling can result in significant financial loss, legal issues, and damage to brand reputation. Small character inkjet printers play a pivotal role by providing precise, consistent, and permanent markings that can be easily tracked and recorded.

Accurate and Consistent Coding

One of the key benefits of small character inkjet printers is their ability to produce accurate and uniform markings on every product. Manual coding is prone to mistakes, such as missing or illegible information, which can compromise traceability. Inkjet printers automate this process, ensuring that each product carries correct information, including batch numbers, production dates, and serial codes. Consistent markings allow for quick identification in case of quality issues or recalls.

Versatility Across Packaging Materials

Products in modern manufacturing are packaged in a variety of materials, including plastics, glass, metals, and cardboard. Small character inkjet printers are designed to handle these diverse surfaces, producing clear, durable, and legible markings regardless of the material or shape of the packaging. This versatility ensures that traceability is maintained across all product lines, regardless of packaging variations.

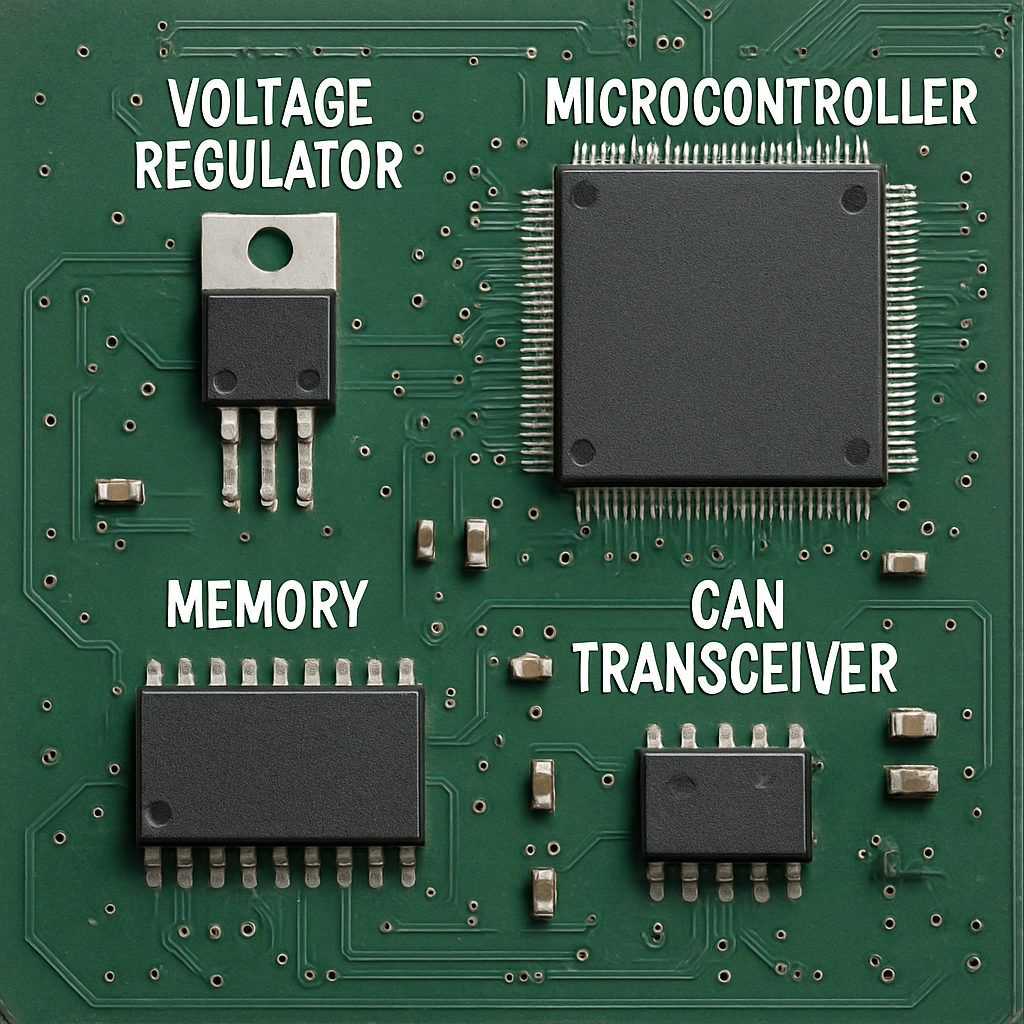

Integration with Automated Systems

Modern production lines are increasingly automated, and small character inkjet printers are designed to integrate seamlessly with these systems. They can work in conjunction with conveyors, robotic arms, and packaging machines, allowing for real-time marking of products as they move through the production line. This integration ensures that every item is coded accurately without slowing down production, enhancing both efficiency and traceability.

Supporting Regulatory Compliance

Many industries, including food and beverage, pharmaceuticals, and consumer goods, are subject to strict regulatory requirements regarding product labeling and traceability. Small character inkjet printers enable manufacturers to comply with these regulations by printing essential information directly on the product or packaging. This ensures that products meet legal standards and can be traced accurately in case of audits or inspections.

Reducing Errors and Product Waste

Manual labeling and coding can result in errors such as incorrect batch numbers or missing information. Such errors not only compromise traceability but also lead to wasted products and additional costs. Small character inkjet printers reduce these risks by automating the process and ensuring that every product carries accurate, readable, and permanent markings. This reduces waste, increases efficiency, and maintains product integrity throughout the supply chain.

Enhancing Supply Chain Management

Traceable products are easier to monitor, manage, and recall if necessary. By using small character inkjet printers, manufacturers can maintain detailed records of each product batch, including production date, manufacturing location, and unique identifiers. This detailed information improves supply chain visibility, enabling manufacturers, distributors, and retailers to track products more effectively and respond quickly to any issues.

Conclusion

Small character inkjet printers are invaluable tools for improving traceability in manufacturing. Their ability to provide accurate, consistent, and permanent markings across various packaging materials ensures that products can be reliably tracked throughout the supply chain. By reducing errors, supporting regulatory compliance, and integrating seamlessly with automated production systems, these printers enhance overall operational efficiency and product safety. Implementing a high-quality small character inkjet printer allows manufacturers to strengthen traceability, protect their brand reputation, and maintain high standards of quality and compliance.