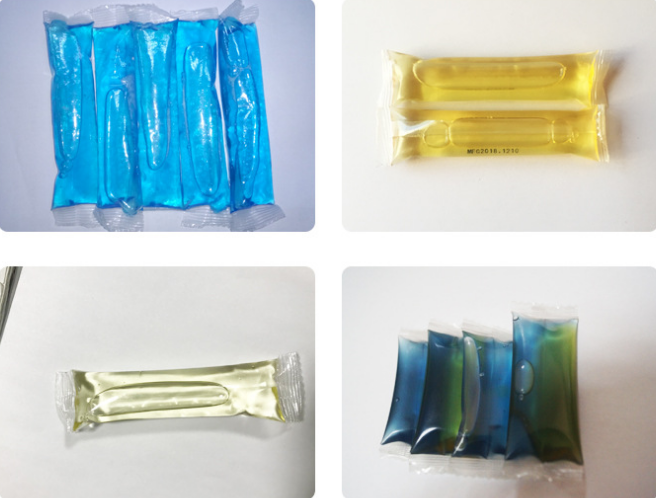

Water soluble films are increasingly used in industries such as consumer products, pharmaceuticals, agriculture, and industrial chemicals due to their eco-friendly nature and convenient application. These films dissolve completely in water, providing precise dosing, reducing waste, and supporting sustainability initiatives. Because these films are often used in sensitive applications, ensuring their quality is critical. A Water Soluble Film Supplier has a range of responsibilities in quality inspection to ensure that each batch meets industry standards and client expectations.

A Water Soluble Film Supplier is responsible for implementing rigorous quality inspection procedures throughout the production process. From raw material selection to final product delivery, suppliers must conduct systematic inspections and tests to guarantee consistency, safety, and compliance. These responsibilities not only protect clients and end-users but also enhance the supplier’s reputation and operational efficiency.

Raw Material Verification

One of the primary responsibilities of a supplier is verifying the quality of raw materials. Polyvinyl alcohol (PVA), the main component in most water soluble films, must meet strict criteria for molecular weight, degree of hydrolysis, and purity. Suppliers also inspect other additives, plasticizers, and stabilizers to ensure that they are non-toxic, compatible, and compliant with regulatory standards.

Raw material verification typically includes chemical analysis, moisture content assessment, and contamination checks. By ensuring that only high-quality inputs are used, suppliers prevent defects, maintain film performance, and reduce the likelihood of recalls or complaints. Proper documentation of raw material inspection is also part of traceability practices.

In-Process Quality Monitoring

Quality inspection is not limited to raw materials; it extends to the production process itself. Suppliers are responsible for monitoring key production parameters such as temperature, humidity, polymer solution viscosity, and drying conditions. Variations in these parameters can affect the film’s tensile strength, thickness, solubility, and clarity.

In-process quality monitoring often involves inline sensors and automated systems that provide real-time data. This allows suppliers to detect deviations early, make immediate corrections, and ensure that the film maintains consistent quality across the entire production batch. Regular calibration of equipment and adherence to standard operating procedures are essential components of this responsibility.

Batch Testing and Certification

Each batch of water soluble film must undergo thorough testing before it is approved for shipment. Suppliers test for mechanical properties such as tensile strength, elongation, and tear resistance. They also evaluate solubility rate, clarity, chemical compatibility, and thickness uniformity. For films used in pharmaceuticals or food applications, additional testing may include microbial contamination, toxicity, and regulatory compliance assessments.

Suppliers are responsible for maintaining detailed batch records that document all test results and certifications. This ensures that clients have access to transparent quality data and supports regulatory compliance with ISO, REACH, FDA, or other applicable standards.

Packaging and Handling Quality

Proper packaging and handling are critical to maintaining film quality. Suppliers are responsible for ensuring that water soluble films are packaged in moisture-resistant materials and protected from environmental factors such as temperature fluctuations and UV exposure. Labels must include batch numbers, storage instructions, and handling guidelines.

Handling inspections during storage and transportation also fall under supplier responsibilities. Films must be protected from mechanical damage, excessive pressure, or contamination that could compromise their performance. Quality inspection at this stage ensures that films reach clients in optimal condition.

Regulatory Compliance and Documentation

A key responsibility of water soluble film suppliers is ensuring regulatory compliance. This includes verifying that films meet safety, environmental, and industry-specific standards. Suppliers maintain documentation such as certificates of analysis, material safety data sheets, and test reports. These records are essential for audits, client verification, and adherence to local or international regulations.

By fulfilling regulatory responsibilities, suppliers provide assurance that the films are safe for their intended use and meet quality benchmarks required by clients and governing bodies.

Continuous Improvement and Feedback Integration

Suppliers are also responsible for continuously improving quality inspection processes. This involves analyzing production and testing data to identify trends, potential risks, or areas for enhancement. Feedback from clients, regulatory audits, and internal inspections informs adjustments to procedures, equipment calibration, and staff training.

Implementing continuous improvement ensures that quality inspection remains effective, reduces defects, and adapts to evolving industry standards. It strengthens the supplier’s ability to consistently deliver high-performance water soluble films.

Training and Workforce Competency

Ensuring quality requires a skilled workforce. Suppliers must train employees on inspection techniques, testing protocols, equipment operation, and regulatory requirements. Competent personnel are essential for accurate assessments, early detection of issues, and proper handling of materials. Regular training programs and certification updates are part of the supplier’s responsibilities to maintain high-quality standards.

Conclusion

Quality inspection is a critical responsibility of water soluble film suppliers, encompassing raw material verification, in-process monitoring, batch testing, packaging, regulatory compliance, continuous improvement, and workforce training. These measures ensure that films meet stringent performance, safety, and environmental standards while satisfying client requirements. By fulfilling these responsibilities, a Water Soluble Film Supplier guarantees that industries can rely on consistent, high-quality films for sensitive applications, enhancing operational efficiency, product reliability, and overall sustainability.